cnc electric oscillating knife machine

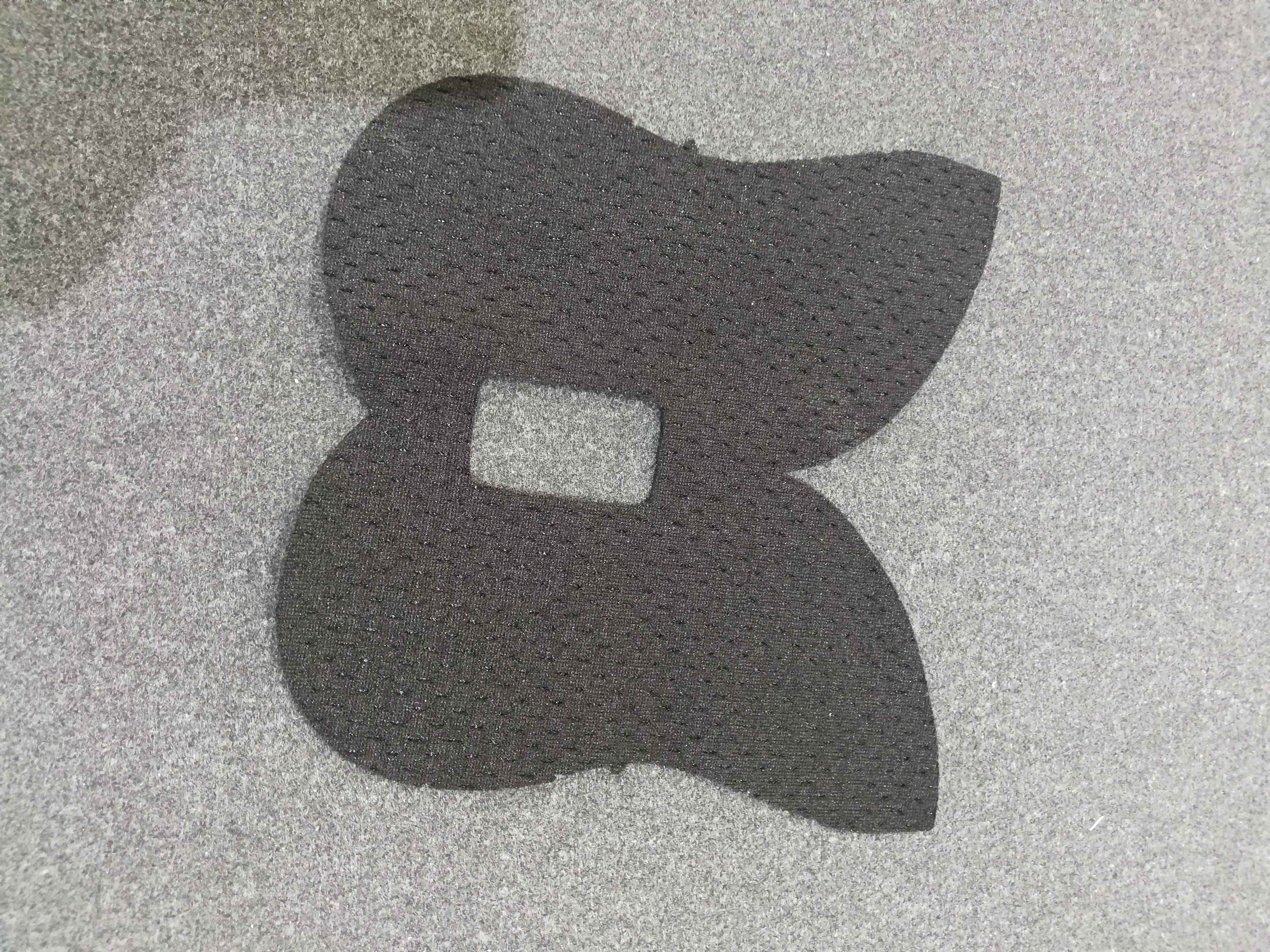

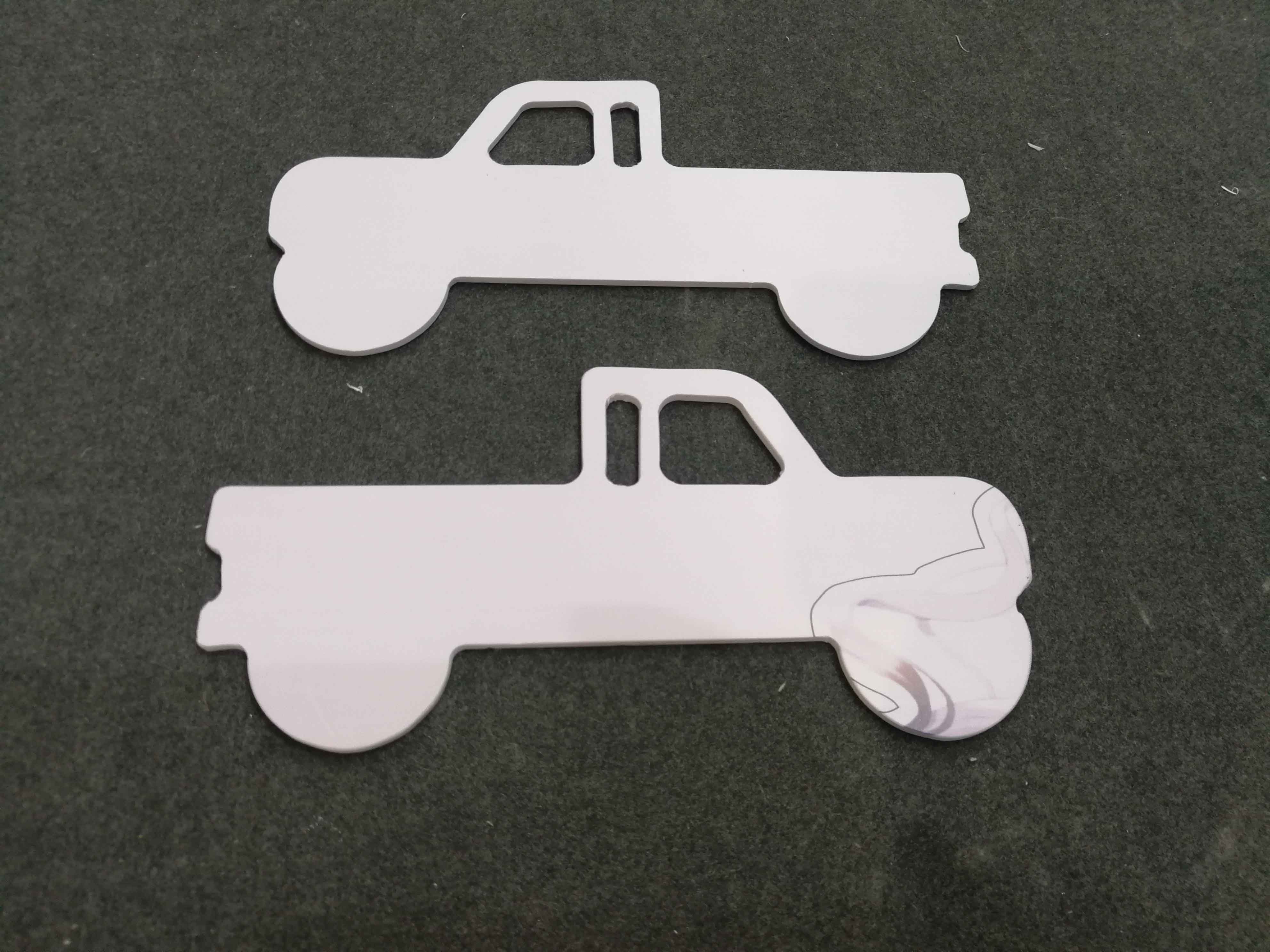

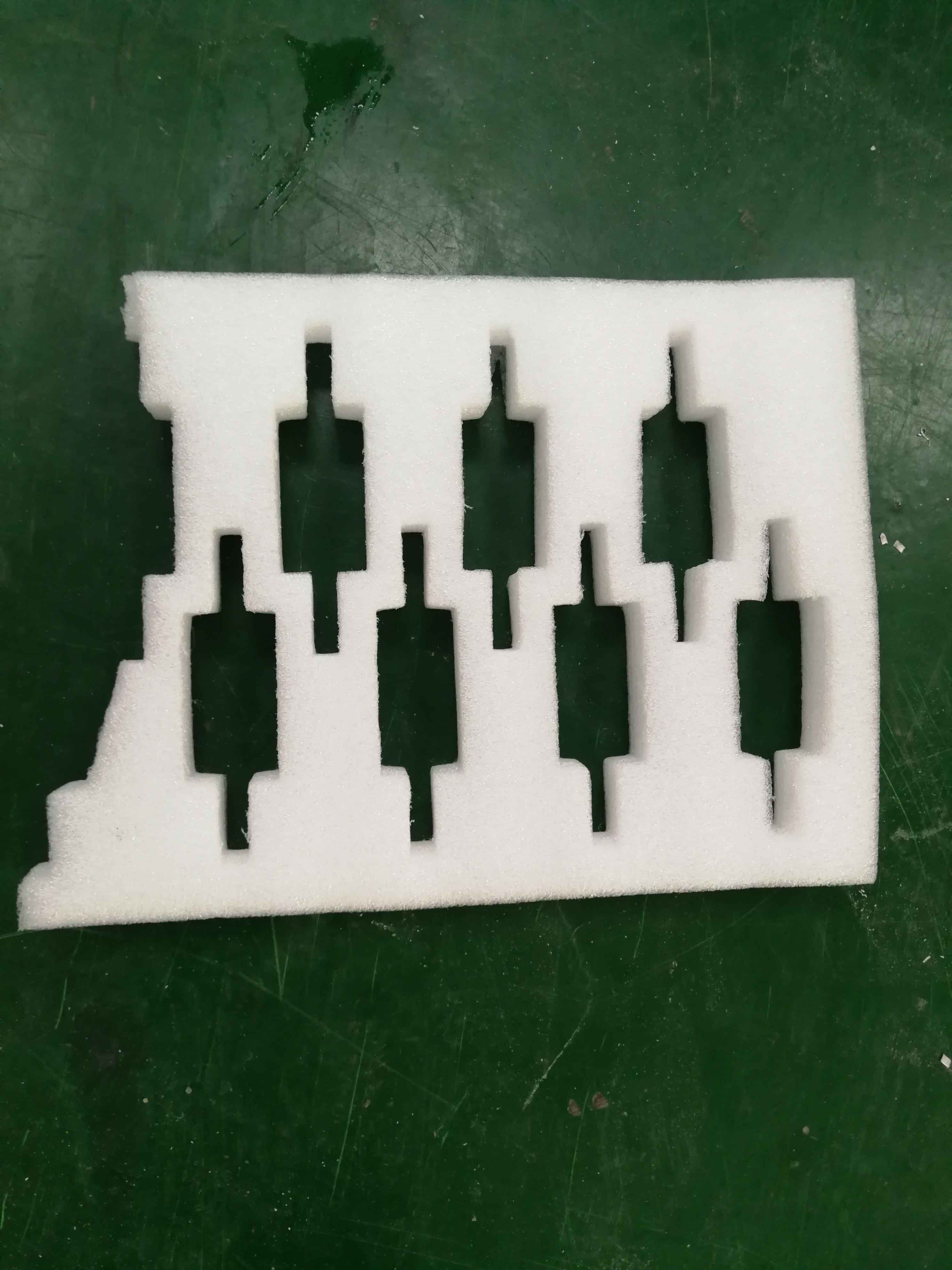

cut Soft materials such as leather, XPE, cloth, paper, sponge, EVA, PVC, KT board

1625 equipment technical parameters:

| Serial number | name | content |

| 1 | model | 1625 (fixed table) / 1625 (automatic feeding) |

| 2 | Feeding method | Manual or automatic feeding |

| 3 | Machine dimensions | Length 3400mmX width 2150mmX height 1370mm |

| 4 | Cutting area | width 1600mmX Length 2500mm |

| 5 | Cutting thickness | ≤25mm |

| 6 | Cutting speed | 0—1500mm |

| 7 | Translation speed | 1500mm |

| 8 | Head configuration | Vibrating knife, electric round knife, V punch, brush, pneumatic knife, CCD positioning (optional) |

| 9 | transfer method | Gear, rack drive |

| 10 | Drive motor | Mitsubishi servo motor |

| 11 | rated power | 10.5KW |

| 12 | Fan | 7.5KW |

| 13 | Rated voltage | 380V |

| 14 | Support file format | PLT\DXF\DWG |

| 15 | Applicable material |

Soft materials such as leather, XPE, cloth, paper, sponge, EVA, PVC, KT board |

| 16 | Applicable industry | Automotive interiors, clothing, advertising, sofas, bags, shoes, etc. |

Accessories description:

1、Vibrating knife

The servo motor drives the upper and lower high-frequency vibration cutting materials of the blade,

which is suitable for cutting medium-density materials and cutting most flexible materials.

(plain leather, leather, soft glass, sponge, etc.)

2、Electric round knife

The motor-driven blade rotates the cutting material at high speed and is suitable for cutting various textile

materials. (eg cloth)

3、Pneumatic knife

It is suitable for cutting high-hardness or thick materials and cutting small-layer flexible materials by

pneumatically driving the upper and lower high-frequency vibration of the blade to cut the material.

(eg cloth, imitation leather, leather, soft glass, sponge, etc.)

4、V knife

The blade cuts the material by dragging, and is suitable for cutting the PVC soft glass chamfering angle,

and the bevel paper opening the V-shaped groove. (eg soft glass, bee paper, etc.)

5、Dragging knife

The blade cuts the material by dragging, and is suitable for cutting stickers, paper sheets, and the like.

6、Indentation knife

A tool for indenting corrugated paper to perfectly fold corrugated paper

7、CCD positioning cutting

The captured target is converted into an image signal and transmitted to a dedicated image processing

system.

The shape information of the target is converted into information based on information such as pixel

distribution and brightness color.

Digitize the signal for positioning.

8、V rush

Effectively punch out the cut when the round knife is cut, effectively matching the efficiency.

9、Pencil

Various process graphics or texts can be drawn on the material to meet the individual production

needs of the customer.

10、Receiving station

The cut pieces can be sent directly to the front receiving table for convenient worker separation.

11、projector

The high-definition projector completely illuminates the work surface during the cutting process,

allowing for a clear comparison of the layout position even on difficult-to-machine shaped materials.

12、Round punch

When the round knife is cut, the small round hole is effectively punched out, which effectively

matches the efficiency.

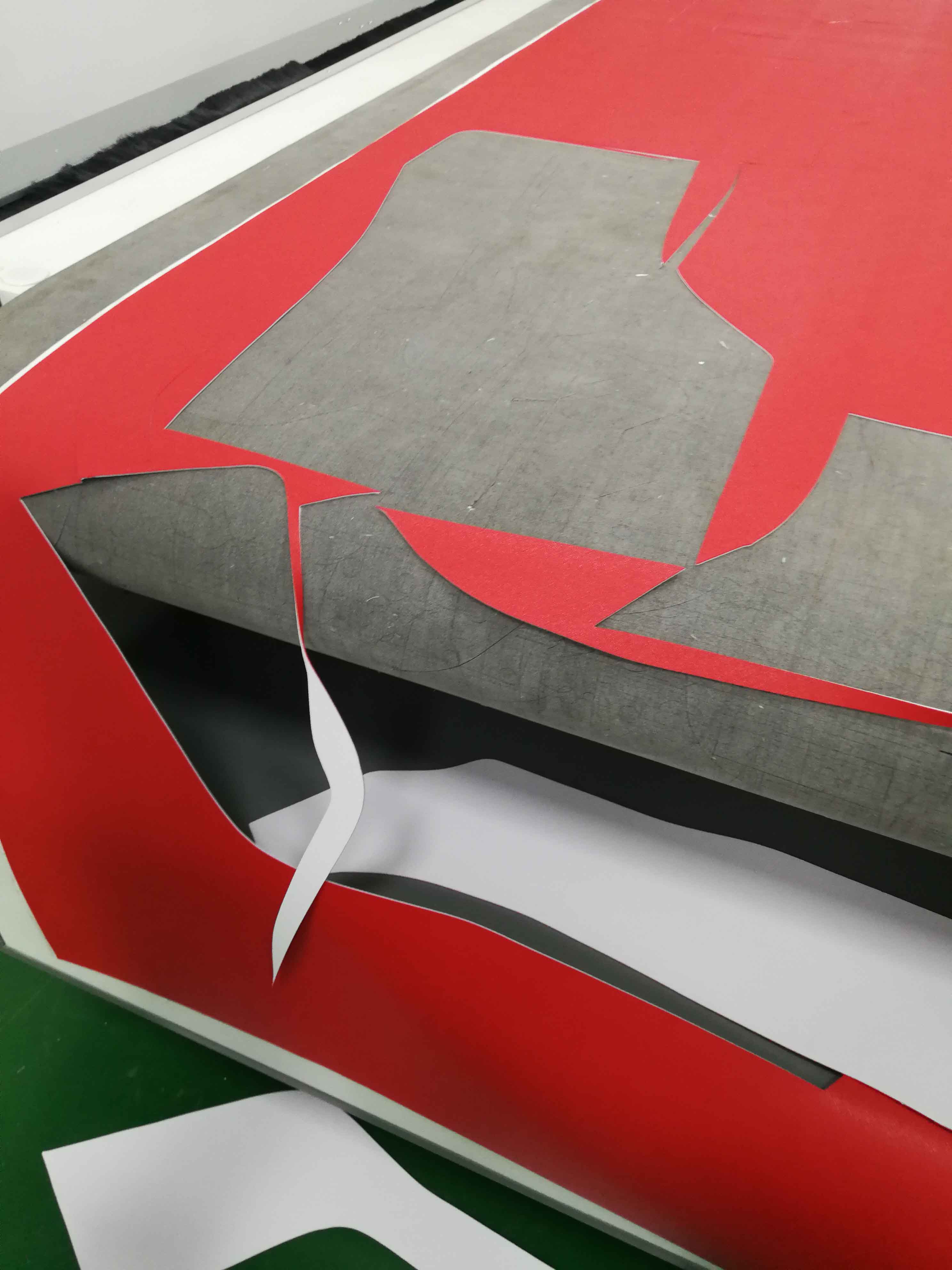

四、The cutting material is:

Corrugated paper, cardboard, white cardboard, gray cardboard, stickers, PVC rubber sheet (soft glass),

KT board, artificial leather, leather, gasket, sponge, prepreg, cloth, acrylic, honeycomb panel, fiberboard,

epoxy Flexible materials such as resin sheets, plexiglass, car mats, wire loops, fiber composites, etc.

Features:

- Suitable for coil materials and industries with certain requirements on production capacity, such

- as soft materials such as printing advertisements, fabrics and leather materials;

2, computer numerical control, automatic cutting, 7-inch LCD industrial touch screen, standard with

Delta servo motor (optional with Panasonic, Mitsubishi, etc.);

- Standard pure aluminum honeycomb platform;

4, can achieve any point positioning cutting, cutting, half-break, infrared positioning, vibrating knife,

round knife, V-knife, indentation knife, dragging knife, milling cutter, CCD positioning, large vision

and many other tools and functions can be selected

- The transmission mode adopts precision guide rail + rack and pinion drive;

- Vacuum pump is used for sucking to ensure the stability of sucking;

7, standard imported felt + humanized feeding rack, intelligent rolling transmission, to achieve non-stop

collection, let the machine play 24 hours;

8, cutting software + nesting software, easy to install and easy to operate;

- Provide remote guidance installation or on-site installation, training, after-sales service, free

- lifetime upgrade software.

Vedio:

| cut carton by oscillating knife machine and press wheel | https://youtu.be/wYCgsMRjplc |

| oscillating knife machine cut kt board good | https://youtu.be/EBwkJEu1lO0 |

| oscillating knife machine cut kt board | https://youtu.be/XRyM43vciTQ |

| oscillating knife machine cut leather good | https://youtu.be/Sj5GleHwfC4 |

| oscillating knife machine cut leather | https://youtu.be/kW4cjZM9rco |

| oscillating knife machine cut car foot mat | https://youtu.be/8VOQ7BNnjm0 |

| round oscillating knife cut fur | https://youtu.be/raBEUQDK8S8 |

| round oscillating knife machine cut fabrics | https://youtu.be/7b2aHE-UqWU |

| cutting artifitial lawn by oscillatting round knife machine | https://youtu.be/OEVjxuxiyD0 |

| cutting fur collur by oscillatting round knife machine | https://youtu.be/S-1a5y-Z0lk |

| cutting single layer leather by oscillatting round knife machine |

https://youtu.be/-LD1i5amqIQ |

There are no reviews yet.